Control Electronics

Our Control Electronics are designed to get the most out of the BLDC motors. They are compact, easy to operate, and offer precise and efficient control. We design and produce every electronic control unit in-house – in this respect, our hardware enables us to react flexibly to different requirements, such as installation space or performance.

Our software is intelligent – we can provide a safety-related control mechanism, redundant control logic, and bidirectional communication.

You have three choices:

You can start with one of our basic control electronics, use a derivative product, or share your distinct requirements with us and we will provide you with a customized solution precisely tailored to meet your individual needs.

BASIC PRODUCT

DERIVATIVE PRODUCT

START FROM SCRATCH

BASIC PRODUCT

Explore our basic products to acquaint yourself with our development and manufacturing capabilities. Primarily focusing on pumps, valves, control electronics, and electric motors, we have crafted a portfolio of products catering to our core markets’ typical requirements.

KEY FEATURES OF OUR CONTROL ELECTRONICS:

DERIVATIVE PRODUCT

We design and produce every electronic control unit in-house – in this respect, our hardware enables us to react flexibly to different requirements, for example, with regard to installation space or performance.

Our software is intelligent – we can provide a safety-related control mechanism, redundant control logic, and bidirectional communication.

Mechatronic drive systems

Our expertise extends beyond the design and production of DC and BLDC motors, gearheads, sensors, and controllers. We possess the capability to seamlessly integrate these drive components into a bespoke mechatronic unit, all within a single housing.

START FROM SCRATCH

We start where others stop. Whether you require a solution for a unique application, challenging environmental conditions, limited construction space, or an integrated approach, we invite you to arrange a conversation with our specialists to explore your project further.

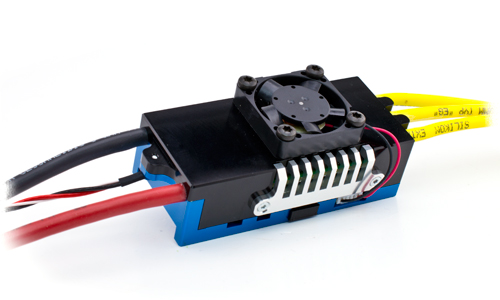

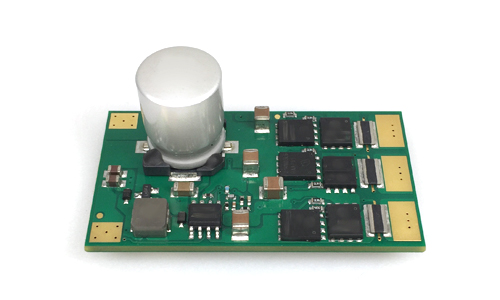

BASIC CONTROL ELECTRONICS

| Foto | Product | Voltage [in V] | Current [in A] | S1 Operation (Continuous current, thermal equilibrium) | S2 Operation (peak at defined duration) | Maximum power [in watts] | Measures [in mm] | Weight [in g] | Max. temperature range [in C°] | Sensors | Commutation type |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SDC 60-130C | 20 - 60 | 200 | 130 | 200 (5s) | 7800 | 109.2 x 53.2 x 38.6 | 250 | 85 | Yes | Block |

| SDC 60-130 | 20 - 60 | 200 | 130 | 200 (5s) | 6000 | 109.2 x 53.2 x 28.6 | 220 | 85 | Yes | Block |

| SDC 60-100C | 20 - 60 | 160 | 100 | 160 (5s) | 6000 | 109.2 x 53.2 x 38.6 | 250 | 85 | Yes | Block |

| SDC 60-100 | 20 - 60 | 160 | 100 | 160 (5s) | 6000 | 109.2 x 53.2 x 28.6 | 210 | 85 | Yes | Block |

| SDC 50-50 | 10 - 56 | 45 | 30 | 2500 | 80 x 60 x 29.2 | 90 | 105 | Yes | Block Sine | |

| SDC 50-30 | 10 - 56 | 30 | 30 | 1500 | 66 x 45 x 29.2 | 46 | 105 | Yes | Block Sine | ||

| SDC 25-75 | 6 - 25 | 140 | 75 | 120 (60s) | 1875 | 77 x 23 x 36 | 160 | 85 | No | Block |

| SDC 25-65 | 6 - 25 | 90 | 65 | 100 (90s) | 1625 | 70 x 19 x 30 | 110 | 85 | No | Block |

| SDC 25-55 | 6 - 25 | 55 | 55 | 65 (5s) | 1375 | 59.5 x 28 x 11 | 49 | 110 | No | Block |

| SDC 25-50 | 10 - 25 | 43 | 43 | 1000 | 80 x 60 x 29.2 | 90 | 105 | Yes | Block Sine | |

| SDC 25-45 | 6 - 25 | 60 | 45 | 60 (120s) | 1125 | 70 x 18 x 30 | 71 | 85 | No | Block |

| SDC 25-40 | 6 - 25 | 40 | 40 | 55 (5s) | 1000 | 59.5 x 28 x 11 | 44 | 110 | No | Block |

| SDC 25-30 | 10 - 25 | 30 | 30 | 750 | 66 x 45 x 29.2 | 0 | 105 | Yes | Block Sine | |

| SDC 15-20 | 15 | 20 | 300 | 45 x 27 | 0 | 0 | No | Block |

In the realm of aerospace, the demands imposed upon the components you procure are of the utmost rigor. It is imperative that your chosen partner demonstrates unwavering reliability and possesses the acumen to resolve any challenge that may arise. They must deliver performance levels that many aspire to achieve. What instills confidence when you place an order? It is our EN 9100 certification that attests to the exceptional quality of our internal quality management within the aerospace domain. Few other industries impose such exacting standards concerning the safety and dependability of individual components. In accordance with our certification for our electric drives and control electronics, we proudly affirm our full compliance with these stringent requirements across our operational domains.

We eagerly anticipate the opportunity to collaborate on your unique project. Please do not hesitate to schedule a consultation at your convenience, with no obligation whatsoever.