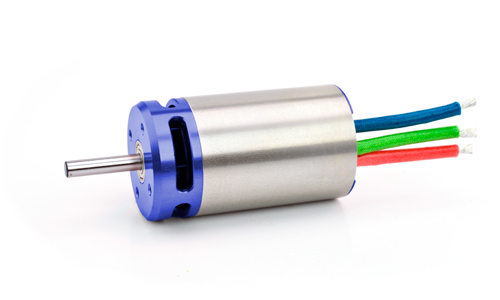

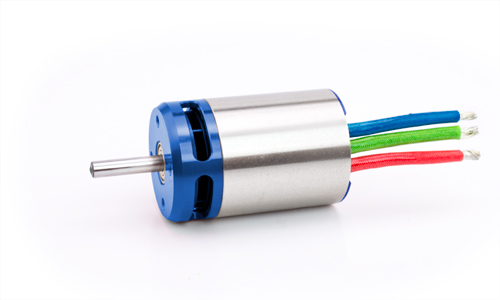

INRUNNERS

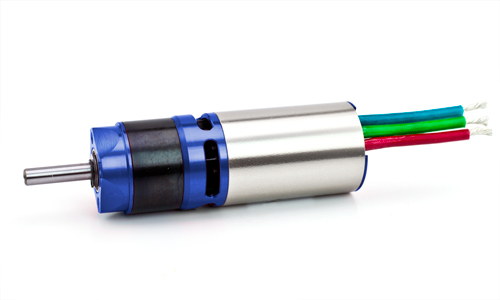

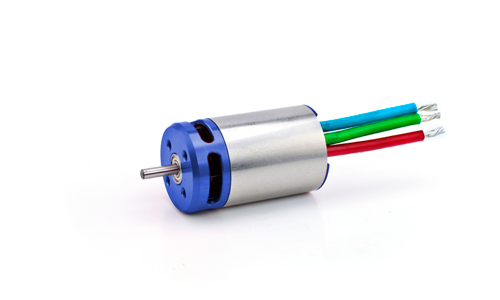

Inrunner BLDC motors are characterized by their internal rotor design, meaning that the rotor (the rotating part) is located inside the stator (the stationary part). This internal rotor configuration allows for a compact and efficient motor design that is ideal for applications requiring high power density and precision.

Unlike traditional brushed motors, BLDC motors do not use physical brushes to transfer electrical current. Instead, they rely on an electronic controller to provide power to the motor. This brushless design eliminates friction, reduces wear and tear, and increases the motor’s lifespan. Furthermore, the absence of brushes results in reduced electromagnetic interference, offering smoother operation and higher efficiency.

At SOBEK, we provide Inrunner BLDC motors designed with cutting-edge technology to meet the most demanding application needs. Our motors are rigorously tested to ensure top-tier performance, efficiency, and reliability. Whether you need a motor for robotics, drones, medical devices, or industrial machinery, our Inrunner motors are engineered to deliver outstanding results.

We offer a range of customizable options, including varying sizes, power outputs, and cooling systems, to ensure the perfect fit for your application. Our team of experts is here to assist you in selecting the right motor and provide ongoing support throughout your project’s lifecycle.

# NEW PRODUCT

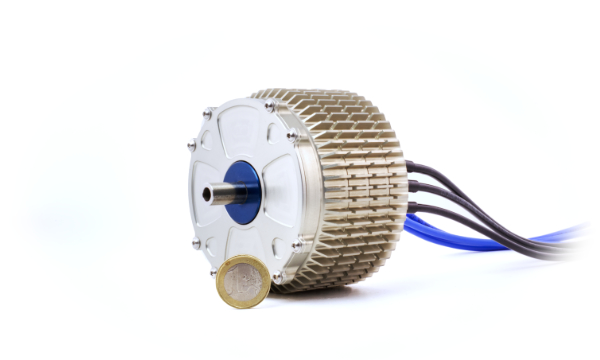

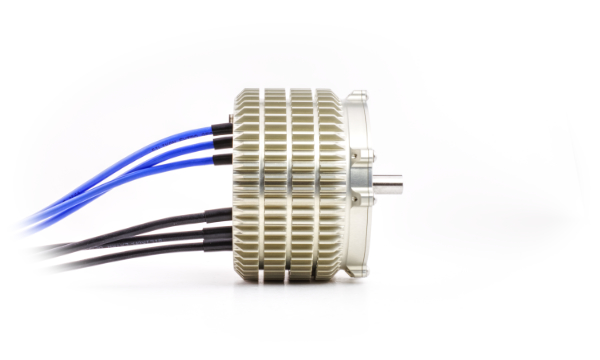

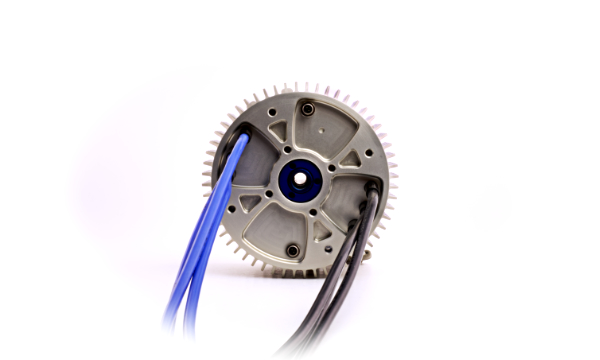

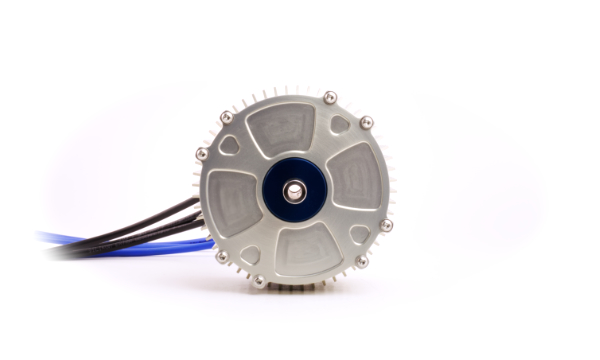

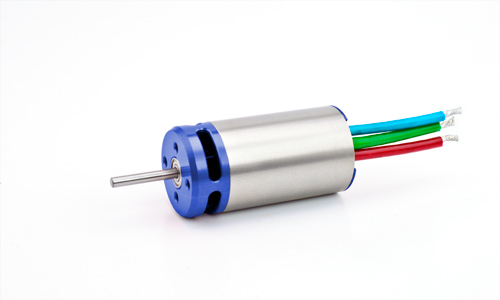

SDI 59STA30DD11-P20-6PH – High-Performance Redundant Motor

The SDI 59STA30DD11-P20-6PH motor is a high-performance, precision-engineered solution designed for demanding applications. Its redundant 2x 3-phase winding ensures maximum reliability and operational safety, making it ideal for critical systems requiring fail-safe functionality.

Key Features:

High-Speed Performance – Up to 12,000 RPM

Optimized Efficiency – Specific speed of 295 RPM/V, adjustable via winding configuration

Redundant 2x 3-Phase Winding – Increased reliability

Integrated Temperature Sensor – Enhanced protection and monitoring

Robust Design – IP54 protection class for durability in tough environments

📌 The KV value can be adjusted. The listed performance data applies to this specific KV configuration.

With its cutting-edge technology, the SDI 59STA30DD11-P20-6PH is the perfect choice for applications requiring high performance, redundancy, and durability.

Technical Information:

- Motor Type: SDI 59STA30DD11-P20

- Bearing Type: 2RS

- Specific Speed @ SOBEK Auto-Timing: 295 RPM/V ±5%

- Max Speed: 12,000 RPM

- No-Load Current @ 36V: 2x 2.5 A ±5%

- Weight: 1040 g

- Inner Resistance: 2x 14 mΩ ±5%

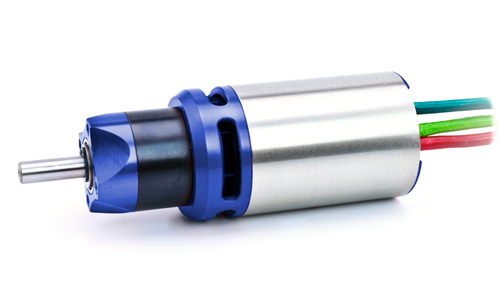

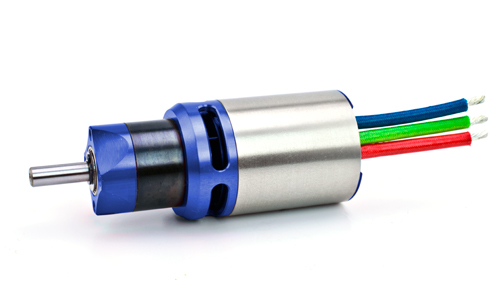

BASIC MOTORS – INRUNNERS

| Variant | U/min/V | Shaft diameter [mm] | Weight [g] | Continuous power [W] | Max. speed [1/min] | Poles | Outer diameter [mm] | Length motor [mm] | Gear ratio |

|---|---|---|---|---|---|---|---|---|---|

| SDI 3627-3000-2 | 3000 | 5 | 260 | 950 | 50000 | 2 | 36 | 63.5 | |

| SDI 3627-2400-2 | 2400 | 5 | 260 | 950 | 50000 | 2 | 36 | 63.5 | 6,7:1 |

| SDI 3627-2200-2 | 2200 | 5 | 260 | 950 | 50000 | 2 | 36 | 63.5 | |

| SDI 3627-2000-2 | 2000 | 5 | 260 | 950 | 50000 | 2 | 36 | 63.5 | |

| SDI 3627-1700-2 | 1700 | 5 | 260 | 950 | 50000 | 2 | 36 | 63.5 | |

| SDI 3627-1600-2 | 1600 | 5 | 260 | 960 | 50000 | 2 | 36 | 63.5 | |

| SDI 3627-3800-2 with gearbox | 3800 | 6 | 320 | 950 | 50000 | 2 | 36 | 89 | 6,7:1 |

| SDI 3627-3000-2 with gearbox | 3000 | 6 | 320 | 950 | 50000 | 2 | 36 | 89 | 6,7:1 |

| SDI 3627-2400-2 with gearbox | 2400 | 6 | 320 | 950 | 50000 | 2 | 36 | 89 | 6,7:1 |

| SDI 3627-2200-2 with gearbox | 2200 | 6 | 320 | 950 | 50000 | 2 | 36 | 89 | 6,7:1 |

| SDI 3627-2000-2 with gearbox | 2000 | 6 | 320 | 950 | 50000 | 2 | 36 | 89 | 6,7:1 |

| SDI 3627-1700-2 with gearbox | 1700 | 6 | 320 | 950 | 50000 | 2 | 36 | 89 | 6,7:1 |

| SDI 3627-1600-2 with gearbox | 1600 | 6 | 320 | 950 | 50000 | 2 | 36 | 89 | 6,7:1 |

| SDI 3618-5800-2 | 5800 | 5 | 200 | 750 | 50000 | 2 | 36 | 54.5 | |

| SDI 3618-3600-2 | 3600 | 5 | 200 | 750 | 50000 | 2 | 36 | 54.5 | |

| SDI 3618-3000-2 | 3000 | 5 | 200 | 750 | 50000 | 2 | 36 | 54.5 | |

| SDI 3618-2600-2 | 2600 | 5 | 200 | 750 | 50000 | 2 | 36 | 54.5 | |

| SDI 2827-5000-2 | 5000 | 3.17 | 150 | 450 | 50000 | 2 | 28 | 54.5 | |

| SDI 2827-4300-2 | 4300 | 3.17 | 150 | 450 | 50000 | 2 | 28 | 54.5 | |

| SDI 2827-3800-2 | 3800 | 3.17 | 150 | 450 | 50000 | 2 | 28 | 54.5 | |

| SDI 2827-3400-2 | 3400 | 3.17 | 150 | 450 | 50000 | 2 | 28 | 54.5 | |

| SDI 2827-3100-2 | 3100 | 3.17 | 150 | 450 | 50000 | 2 | 28 | 54.5 | |

| SDI 2827-2600-2 | 2600 | 3.17 | 150 | 450 | 50000 | 2 | 28 | 54.5 | |

| SDI 2827-5800-2 with gearbox | 5800 | 6 | 260 | 750 | 50000 | 2 | 36 | 80 | 6,7:1 |

| SDI 2827-5000-2 with gearbox | 5000 | 5 | 210 | 450 | 50000 | 2 | 28 | 79 | 5,2:1 |

| SDI 2827-4300-2 with gearbox | 4300 | 5 | 210 | 450 | 50000 | 2 | 28 | 79 | 5,2:1 |

| SDI 2827-3800-2 with gearbox | 3800 | 5 | 210 | 450 | 50000 | 2 | 28 | 79.5 | 5,2:1 |

| SDI 2827-3600-2 with gearbox | 3600 | 6 | 260 | 750 | 50000 | 2 | 36 | 80 | 6,7:1 |

| SDI 2827-3400-2 with gearbox | 3400 | 5 | 210 | 450 | 50000 | 2 | 28 | 79 | 5,2:1 |

| SDI 2827-3100-2 with gearbox | 3100 | 5 | 210 | 450 | 50000 | 2 | 28 | 79 | 5,2:1 |

| SDI 2827-3000-2 with gearbox | 3000 | 6 | 260 | 750 | 50000 | 2 | 36 | 80 | 6,7:1 |

| SDI 2827-2600-2 with gearbox | 2600 | 5 | 210 | 450 | 50000 | 2 | 28 | 79 | 5,2:1 |

| SDI 2827-2600-2 with gearbox 6,7:1 | 2600 | 6 | 260 | 750 | 50000 | 2 | 36 | 80 | 6,7:1 |

| SDI 2818-3900-2 | 3900 | 3.17 | 110 | 250 | 50000 | 2 | 28 | 45.5 | |

| SDI 2818-3400-2 | 3400 | 3.17 | 110 | 250 | 50000 | 2 | 28 | 45.5 | |

| SDI 2818-2700-2 | 2700 | 3.17 | 110 | 250 | 50000 | 2 | 28 | 45.5 | |

| SDI 2818-3900-2 with gearbox | 3900 | 5 | 170 | 250 | 50000 | 2 | 28 | 70 | 5,2:1 |

| SDI 2818-3400-2 with gearbox | 3400 | 5 | 170 | 250 | 50000 | 2 | 28 | 70 | 5,2:1 |

| SDI 2818-2700-2 with gearbox | 2700 | 5 | 170 | 250 | 50000 | 2 | 28 | 70 | 5,2:1 |

You have three choices:

You can start with one of our basic electric drives, use a derivative product, or share your distinct requirements with us and we will provide you with a customized solution precisely tailored to meet your individual needs.

BASIC PRODUCT

DERIVATIVE PRODUCT

START FROM SCRATCH

BASIC PRODUCT

Explore our basic products to acquaint yourself with our development and manufacturing capabilities. Primarily focusing on pumps, valves, control electronics, and electric motors, we have crafted a portfolio of products catering to our core markets’ typical requirements.

KEY FEATURES OF OUR ELECTRIC DRIVES:

DERIVATIVE PRODUCT

Choosing the right motor can reduce energy and maintenance costs, as the application runs with the defined load and precision. Designing the motor requires a balance between torque, speed, and inertia. Considering the desired power density, we focus on the best operating point to achieve our motors’ optimum efficiency.

Our variants offer customized drive solutions derived from our Stock Service product range. These adaptations encompass winding modifications, diverse shaft options, alternate brush choices, varying transmission ratios for gears, and using different materials for gear wheels. These adjustments result in drives precisely tailored to your specific requirements.

Mechatronic drive systems

Our expertise extends beyond the design and production of DC and BLDC motors, gearheads, sensors, and controllers. We possess the capability to seamlessly integrate these drive components into a bespoke mechatronic unit, all within a single housing.

START FROM SCRATCH

We start where others stop. Whether you require a solution for a unique application, challenging environmental conditions, limited construction space, or an integrated approach, we invite you to arrange a conversation with our specialists to explore your project further.

In the realm of aerospace, the demands imposed upon the components you procure are of the utmost rigor. It is imperative that your chosen partner demonstrates unwavering reliability and possesses the acumen to resolve any challenge that may arise. They must deliver performance levels that many aspire to achieve. What instills confidence when you place an order? It is our EN 9100 certification that attests to the exceptional quality of our internal quality management within the aerospace domain. Few other industries impose such exacting standards concerning the safety and dependability of individual components. In accordance with our certification for our electric drives and control electronics, we proudly affirm our full compliance with these stringent requirements across our operational domains.

We eagerly anticipate the opportunity to collaborate on your unique project. Please do not hesitate to schedule a consultation at your convenience, with no obligation whatsoever.